What is Dye Sublimation printing?

Dye Sublimation printing is the process where ink is sublimated into the fabric (100% nylon / polyester) at high temperature.

What you get is a fully all-over printed apparels with designs ink inside the fabric (smooth feel of the T-Shirt).

Recent Custom Sublimation Printing Apparels

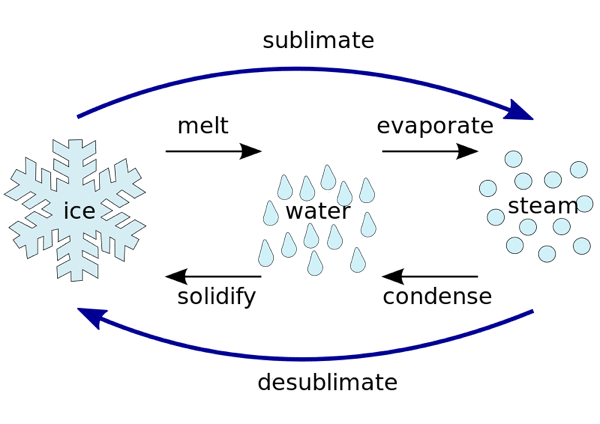

The ink undergoes a process from solid to gaseous state without undergoing the liquid state.

This process of sublimation allows the ink to be part of the fabric. At the end, it feels that you printed directly onto the fabric itself, as you cannot feel the ink, unlike silk screen printing or DTG Printing where you can feel the ink.

The unique feature of sublimation printing is precisely that the ink is in the fabric.

This is in contrast to other digital transfer methods such as digital heat transfer printing where the printing is done on the exterior of the fabric.

This makes it a unique printing method when it comes to T-Shirt Printing Singapore cheap. At Meowprint, our Sublimation printing services have a lead-time of about 3-5 weeks from the start of processing of our orders.

With only a minimum order quantity of 50 pieces, you are able to customize your all-over sublimation printed apparels and products.

1. How did Sublimation printing come about?

Interestingly, the origins of sublimation printing are a result of the discovery of piezoelectricity and research of inkjet printers. Noel de Plasse first invented sublimation printing in 1957.

He cleverly discovered that high temperatures could cause specific dyes to sublimate. But, this was later discovered that his dyes didn’t really sublimate and that it was more of a dye-diffusion process.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

The subsequent events that took place are then subject to debate. On the one hand, it has been said that Nobutoshi Kihara, who worked for Sony, adapted dye diffusion into a proper dye-sublimation process primarily for the purposes of printing video stills.

But, at the same time, across the other side of the world, Wes Hoekstra in California was thought to have developed the first computer-driven sublimation system.

What’s important to know is that – the advance of technology and the increased demand for such high quality products have caused a increase in the prevalence of sublimation printing today.

2. What is Sublimation process?

We mentioned above a very brief idea of what sublimation printing is.

If you are eager to learn more about it now, fret not, because this section will be dedicated to elaborating on the process of sublimation printing as well as the equipment and materials that you might need.

The idea of sublimation is crucial in this process. To refresh your memories from the glorious days in schools, sublimation is essentially the process where a substance transitions from the solid state into the gaseous state.

The important thing to note here is that the liquid state is leapfrogged. Conversely, the process of deposition is the opposite.

In this process, a substance transitions from the gas phase directly into a solid, again leapfrogging the liquid phase.

Do keep this in mind, as this will then help you understand the later sections of this article.

What you get is a fully all-over printed apparels with designs ink inside the fabric (smooth feel of the T-Shirt).

Sublimation Printing Process

3. Process of Sublimation T-Shirt printing (Step-by-step)

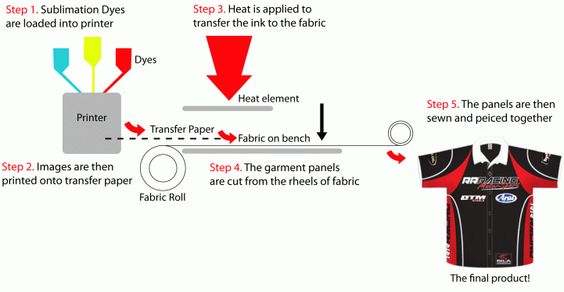

Basically, successful sublimation printing can be done in this two part process :

- Printing the design onto a special transfer paper using sublimation inks.

- Using a heat press to transfer the design on the special paper (in Step 1) onto the t-shirt

As you can see from the process above, the crucial equipment used in sublimation printing is:

- A sublimation printer, sublimation inks and a software to control your printer.

- Transfer paper (or sublimation paper)

- A heat press machine

Sublimation Printing Process

i) Printing the design onto the transfer paper

The sublimation printing process begins with a printer and unique sublimation inks.

A dye-sublimation printer uses heat to transfer dye onto various materials. Sublimation ink is unique because of its ability to convert from a solid to a gas without going through a liquid form.

- First, the printing process starts with films that contain dyes (ink). The film typically includes 4 color pigments, cyan magenta, yellow and gray.

- Typically, this could either take the form of a single film with 4 layers of colors, or 4 individual films for each color.

- Then, during the printing process the pigments in these films are heated up and transferred onto the transfer paper through a piezoelectric print head. This print head is capable of printing at least 200 different shades of each color!

- The pigments will then transition into gaseous state and leave the film.

- The pigments will subsequently cool and solidify onto the transfer paper. This is the sublimation process!

ii) Transferring design on the paper onto the t-shirt

Now that you have successfully printed your design onto a sublimation paper, the next step is to transfer this onto the final product – your t-shirts.

In order to do this, a heat press is required. With the application of heat and pressure for a period of time, the design can be imprinted onto the t-shirt. The period of time is dependent on the dye formulation and the type of fabric of the t-shirt.

Again, this requires the process of sublimation all over again. The high temperature from the heat press causes the dye on the paper to sublime into a vapor/gas.

At the same time, the pores of the t-shirt that you’re pressing heat onto will also open up. Once pressure is released and heat is cooled, the dye will then turn back into solid form.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

The result? The pores of the t-shirt will then close and the gas reverts back to a solid state.

Because the pores of the t-shirt have encapsulated the ink whilst it was closing, the ink is now part of the fabric.

iii) The difference between Inkjet and Sublimation Printers

The comparison between inkjet and sublimation printers can be useful to further show how sublimation printers work!

One interesting fact about the sublimation printer is that the color produced by it is of a higher quality than typical inkjet printers .

For one, inkjet printers print by spraying droplets of liquid ink from the nozzles. But if you magnify this result, you can still somewhat see the primary colors.

On the other hand, sublimation printers are capable of producing images with continuous tones of colors. These colors physically blend together.

We have shared much technical details about the process of sublimation printing on t-shirts (that’s our forte!) Well, if you need more visual reference, check out the video below.

4. Advantages & Disadvantages of Sublimation Printing

To help you make a better choice when deciding on the type of T-shirt printing services, we have also come up with some advantages and disadvantages of dye sublimation printing method.

Sublimation printing is also used to customize gifts for designs that need full color all over prints. If you need customized corporate gifts singapore, we also offer a wide range of over 1,000 unique gifts for you to customise!

Advantages

- An all-over print effect on the t-shirts is achieved as ink is printed from seam-to-seam.

- You can’t feel the ink as it will become part of the fabric and the end product is a soft-hand feel.

- Long-lasting quality design as the printing becomes part of the fabric.

- Thousands of colors to choose from!

Disadvantages

- Type of t-shirt is restricted as only certain types of fabric are suitable for sublimation printing. eg suitable for 100% nylon / polyester material only.

- The color of the t-shirt is restricted to white or light-coloured ones.

5. Sublimation printing can be used for the following Products from our T-Shirt Printing catalogue.

T-Shirts & Apparels

- ✅ All T-Shirts

- ✅ All Polo T-Shirts

- ✅ All Jackets & Hoodies

- ✅ All Singlets

- ✅ All Caps & Hats

- ✅ All Workwear

- ✅ All Corporate Uniforms

- ✅ All Shorts & Pants

Corporate Gifts

- ✅ All Lanyards

- ✅ All Custom Patches

- ✅ All Pins & Badges

- ✅ All Umbrellas

- ✅ All Towels

- ✅ All Small Promo Gifts

- ✅ All Wearables

- ✅ All Drinkware

- ✅ All Lifestyle Products

- ✅ All Office Supplies

- ✅ All Customised Pens

- ✅ All Custom Bags

- ✅ All Electronic Gadgets

- ✅ All Custom USB Flash Drive

- ✅ All Mobile Accessories

- ✅ All Travel Accessories

- ✅ All Personal Care

6. Recommendations for Sublimation printing by MeowPrint

Sublimation printing is recommended for customers who are looking to print all-over full-coloured designs.

Popular apparels would be cycling apparels & jersey printed apparels as well as retail fashion brands.

For cycling team apparel, you can match this method along with embroidery for that professional team outlook.

Many of our corporate customers opt for sublimation printing as their designs and customization of colors throughout the apparel can be very complex.

The costs is not cheap but you get one-of-a-kind corporate apparel!

If you need cotton or honeycomb material for customization, then this method is not suitable.

However you can check out our custom-made services as well.