What Is Foil Printing?

Foil printing is a versatile printing technique that adds metallic or pigmented foils to materials like fabric, paper, or leather.

You’ll find three main methods: hot foiling uses heat and pressure, cold foiling employs UV-activated adhesives, and digital foiling allows for custom designs without dies. It’s particularly effective for creating eye-catching logos, luxury branding, and special event merchandise.

While the process requires specific equipment and expertise, it produces durable, vibrant results that maintain their appeal through multiple washes. The technique’s unique ability to enhance brand perception through premium finishes opens up exciting possibilities for your marketing materials.

Key Takeaways

- Foil printing is a decorative technique that applies metallic foils to materials like paper and fabric using heat or pressure.

- It creates luxurious, eye-catching metallic effects through three main methods: hot foiling, cold foiling, and digital foiling.

- The process requires specialized equipment and is compatible only with laser printers, not inkjet printers.

- Foil printing produces durable, vibrant finishes that maintain their appearance through multiple washes on garments.

- Popular applications include custom t-shirts, business cards, packaging, and high-end retail apparel for premium brand experiences.

How does Foil printing work?

Through specialized techniques, foil printing creates stunning metallic designs by transferring thin metallic films onto various surfaces.

You’ll find three main methods used in modern foil printing, each offering unique advantages for achieving different foil textures and foil colors.

For optimal results, prints should be created using a laser printer only, as inkjet printers are not compatible with the foiling process.

- Hot foiling delivers premium results using heat and pressure

- Cold foiling provides flexibility with UV-activated adhesives

- Digital foiling enables quick, customizable designs without dies

The process selection depends on your specific needs, with each method offering distinct characteristics:

| Method | Temperature | Pressure | Time | Speed | Cost |

|---|---|---|---|---|---|

| Hot | High | High | Longer | Slower | Higher |

| Cold | Room | Medium | Medium | Faster | Medium |

| Digital | Low | Low | Quick | Fastest | Lower |

Whether you’re creating luxury business cards or eye-catching packaging, understanding these methods helps you choose the right approach.

Hot foiling excels at producing deep, rich metallic effects, while cold foiling offers excellent detail in high-speed production.

Digital foiling provides the flexibility to produce small runs with quick turnaround times, making it ideal for customized projects requiring various foil colors and textures.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

Foil printing compared to other printing methods

When comparing foil printing to other methods, you’ll discover unique advantages regarding visual impact and durability. Different printing techniques offer varying benefits for specific applications, with foil printing standing out for its metallic finish and professional appearance.

Modern digital foil printing eliminates the need for custom dies while maintaining excellent quality. Consider these key factors:

- Surface compatibility and material requirements

- Production speed and setup complexity

- Cost per unit for different run sizes

| Method | Best For | Limitations |

|---|---|---|

| Foil | Metallic effects, luxury items | Limited color options |

| DTG/DTF | Full-color designs, photos | No metallic finish |

| Sublimation | All-over prints, synthetics | Won’t work on cotton |

Foil vs Silkscreen Printing

Foil printing and silkscreen printing stand out from each other in several key aspects. While foil stamping creates luxurious, reflective finishes using heat and pressure, silk screen printing offers versatility through a mesh-based stencil process.

You’ll find these methods differ markedly in both application and results. The dwell time during foil application significantly impacts the final quality of metallic transfers.

- Foil stamping produces highly reflective, metallic finishes ideal for luxury branding

- Silk screen printing allows for intricate designs and multiple color options

- Both methods work well on vinyl, but each has unique material compatibility

| Feature | Foil Stamping | Silk Screen |

|---|---|---|

| Cost | Higher | Lower |

| Design Detail | Limited | Extensive |

| Finish | Glossy | Matte |

| Color Options | Metallic | Multiple |

| Production Speed | Slower | Faster |

When choosing between these methods, consider your specific needs. Foil stamping excels in creating eye-catching metallic effects and luxury impressions, though it’s more expensive and limited in design complexity.

Silk screen printing offers greater design flexibility and cost-effectiveness, especially for larger runs, but won’t achieve the same reflective qualities. For best results, match your project requirements to each method’s strengths.

Foil vs Direct-To-Film Printing

Determining the best printing method between foil and direct-to-film (DTF) requires understanding their distinct capabilities and limitations.

Foil applications excel in creating premium, metallic finishes ideal for luxury packaging and singapore corporate gifts such as notebooks, while DTF advantages include versatility across various substrates and superior detail reproduction.

Key differences to evaluate:

- Foil printing requires specialized equipment and custom dies, increasing setup costs

- DTF offers greater design flexibility with intricate patterns and gradients

- Both methods provide durable results, but DTF typically offers better wash resistance

| Feature | Foil Printing | DTF Printing |

|---|---|---|

| Cost | Higher setup, lower volume | Higher initial, lower running |

| Detail | Limited fine detail | Excellent detail handling |

| Durability | Surface embedded | Deep fabric penetration |

When selecting between these methods, assess your specific needs. Foil printing shines in creating luxurious, metallic effects on business cards and wedding invitations, though it’s limited in detail work.

DTF printing offers exceptional versatility and handles complex designs well, making it ideal for fabric applications and large-scale productions where detail preservation is essential.

Foil vs Direct-To-Garment Printing

Choosing between foil and direct-to-garment (DTG) printing methods isn’t always straightforward, as each offers distinct advantages for different applications.

When considering foil printing benefits, you’ll find they excel in creating eye-catching metallic finishes and work exceptionally well on various fabric types without pre-treatment. DTG printing requires garment pretreatment for proper ink adhesion and color vibrancy.

Key foil printing applications include:

- Luxury brand designs requiring metallic accents

- High-end fashion pieces with bold graphic elements

- Premium promotional materials needing distinct visual appeal

| Comparison | Foil Printing | DTG Printing |

|---|---|---|

| Fabric Types | Wide range including silk, leather | Primarily cotton-based |

| Cost Factor | Higher initial investment | Lower setup costs |

| Design Capability | Limited to solid elements | Full-color designs |

While DTG printing offers excellent color reproduction and gradient capabilities, foil printing provides a premium tactile finish that’s particularly striking on dark fabrics.

You’ll find foil printing especially valuable when creating upscale designs that require metallic elements, though it typically comes at a higher cost per unit than DTG.

For businesses targeting luxury markets, the distinctive metallic finish and versatile fabric compatibility make foil printing an attractive option despite its higher price point.

Foil vs Digital Heat Press Printing

Through the lens of print technology, the differences between foil and digital heat press printing become quite clear. While both methods transfer designs onto substrates, foil application techniques offer distinct advantages for achieving metallic and reflective finishes that digital heat press can’t match.

Modern manufacturing benefits from drop-on-demand technology that enables gradient effects unavailable in traditional printing methods.

- Cold foil printing enables variable data and intricate patterns

- Hot foil stamping provides premium tactile effects

- Digital heat press excels in fabric applications

When selecting between these methods, consider your specific project requirements and material constraints. Foil design flexibility varies considerably between hot and cold techniques, with cold foil offering greater versatility for complex designs.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

| Feature | Foil Printing | Digital Heat Press |

|---|---|---|

| Surface Type | Flat paper, cards | Fabrics, textiles |

| Finish | Metallic, reflective | Matte, semi-gloss |

| Durability | High | Moderate |

| Setup Time | Variable | Quick |

| Cost Structure | Higher initial | Lower initial |

For business applications requiring premium finishes on paper products, foil printing delivers superior results. However, if you’re working primarily with textiles or need quick turnaround times, digital heat press might be your better option.

Foil vs Sublimation Printing

While digital heat press and foil printing each serve distinct purposes, comparing foil to sublimation printing reveals another set of important differences.

When you’re choosing between these methods, understanding their distinct capabilities will help you make the right choice for your project. Cold foil processes provide UV-curable adhesive applications that integrate seamlessly with standard printing workflows.

- Sublimation benefits include superior detail reproduction and unlimited color options

- Foil limitations restrict intricate designs and color variations

- Both methods work well on different substrate materials

| Feature | Foil Printing | Sublimation Printing |

|---|---|---|

| Detail Level | Limited fine details | High resolution details |

| Color Options | Single metallic colors | Full color spectrum |

| Durability | Surface-level adhesion | Penetrates material |

| Material Range | Paper, card stock | Polyester, ceramics |

The key distinction lies in their application process and end results. Foil printing excels at creating metallic finishes and striking visual effects, particularly on paper products.

However, sublimation offers greater versatility in both design complexity and material compatibility.

If you’re working with detailed images or need vibrant colors, sublimation might be your better choice. For projects requiring metallic elements or specialty finishes, foil printing remains the go-to option.

Pros and Cons of Foil Printing

When you’re considering foil printing for your project, you’ll need to weigh its impressive benefits against several practical challenges.

While foil printing offers stunning visual effects with metallic finishes and excellent durability across various materials, you’ll face higher setup costs and potential technical complexities during production.

The process requires careful planning and specialized equipment, but the end result can provide your printed materials with a premium, eye-catching appearance that standard printing methods can’t match. The versatility of this technique allows for application on multiple fabric types, including cotton, polyester, and blended materials.

Pros

Discovering the advantages of foil printing reveals numerous compelling benefits for businesses and designers. The visual impact of metallic finishes instantly elevates your brand materials, creating a luxurious and professional appearance that catches the eye. The tactile elements of foil-stamped materials make them more memorable and engaging for customers.

With exceptional design flexibility, you’ll have the freedom to incorporate intricate patterns and detailed elements across various materials, from business cards to product packaging.

When you’re looking to make your materials stand out, foil printing offers these key advantages:

- Enhanced durability that maintains vibrancy through multiple washes and extended use

- Sustainable printing options that don’t compromise environmental responsibility

- Versatile application across different substrates, including paper, cards, and apparel

You’ll appreciate how foil printing creates sharp contrast between metallic elements and base materials, helping your brand differentiate itself in competitive markets.

The technique’s ability to highlight specific features like logos and text guarantees your message commands attention. Plus, the long-lasting quality of foil-printed materials means you’re investing in promotional items that maintain their professional appearance over time, reinforcing your brand’s commitment to excellence.

Cons

Despite its visual appeal, foil printing comes with several notable drawbacks you’ll need to take into account. The most crucial foil stamping challenges involve high initial costs, including investments in metal dies and specialized equipment.

You’ll also face technical hurdles that can affect print quality, such as temperature control and pressure consistency. The process requires expert consultation for optimal results, especially when working with detailed designs.

Material issues present another set of complications. When working with foil printing, you’ll encounter these common limitations:

- Digital toner foiling requires completely smooth card stocks

- Textured materials aren’t suitable for the process

- Limited color options are available for digital foiling

The process inefficiencies can impact your production timeline and bottom line. Each type of foil requires separate runs in hot foil pressing, increasing your production time considerably.

Additionally, foil material issues like coking can occur if machine temperatures aren’t precisely controlled, potentially ruining your materials.

For those new to foil printing, achieving consistent results requires careful attention to machine settings and an understanding of how different materials interact with the foiling process. This learning curve can lead to increased waste and production costs during the initial implementation phase.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

Uses of Foil Printing in Custom T-Shirt Printing

Foil printing has emerged as a popular choice for custom T-shirt printing singapore , allowing you to create eye-catching metallic finishes that stand out from traditional prints.

You’ll find this versatile technique aligning perfectly with current fashion industry trends, particularly in creating high-end retail apparel and custom design applications.

Here’s where you can effectively use foil printing:

- Special event merchandise (concerts, festivals)

- Brand logo enhancements

- Holiday collections

- Athletic wear accents

- Fashion-forward streetwear

You can combine foil printing with other techniques to maximize its impact. For instance, you’ll achieve stunning results by adding metallic accents to existing screen prints or creating layered effects with different ink types. The technique requires a proper heat press setup for successful application.

The process works exceptionally well on 100% cotton garments, giving you the flexibility to experiment with various designs from subtle to dramatic.

When planning your custom Tshirt Printing projects, you can consider these applications:

- Full metallic designs for maximum impact

- Accent details on larger prints

- Pattern highlights

- Text embellishments

- Logo upgrades

Remember that while foil printing requires specific care instructions, it’s an excellent way to enhance your custom apparel’s perceived value and visual appeal.

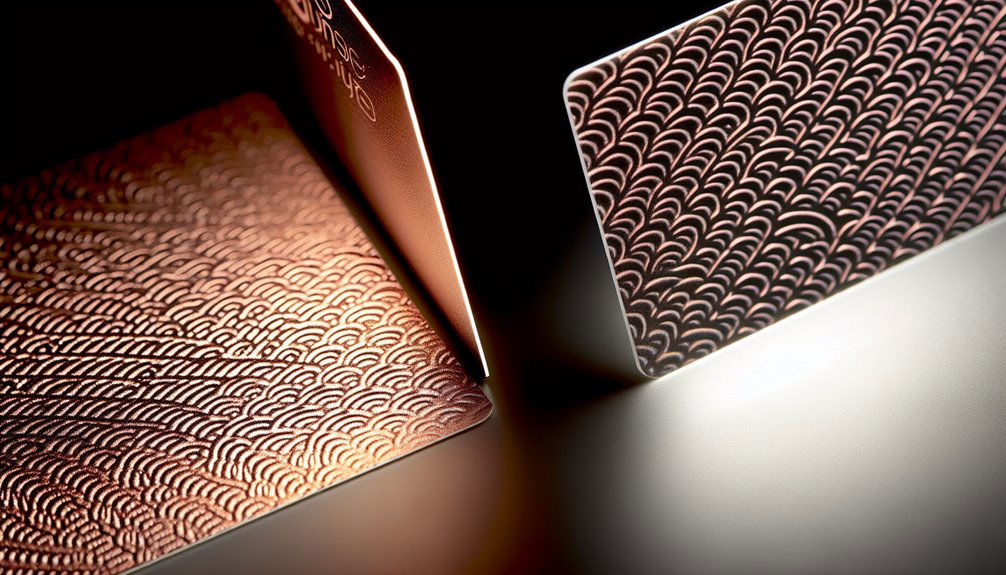

Striking Metallic Brand Designs

When creating striking metallic brand designs, you’ll find that the right combination of foil selection and design preparation makes all the difference in achieving a premium look.

Your brand’s visual impact can be dramatically enhanced through careful selection of metallic finishes, whether you choose classic gold, sophisticated silver, or eye-catching copper tones.

With prints available in sizes from 4×6 to 40×80 inches, you can create impactful branded materials at any scale.

To guarantee successful metallic branding implementation:

- Start with vector-based designs in Adobe Illustrator, optimizing for clean, bold lines.

- Select appropriate foil colors that align with your brand’s aesthetic.

- Consider using multiple foil colors to highlight specific design elements.

- Work closely with suppliers to guarantee proper adhesion and color consistency.

The impact of luxurious finishes on your brand materials is significant. You’ll notice how foil printing instantly elevates business cards, marketing materials, and packaging with a sophisticated sheen that catches light and attention.

For maximum effect, focus on applying metallic elements to logos, company names, and key messaging points where you want to draw the eye.

This technique isn’t just about adding shine—it’s about creating a premium brand experience that resonates with your target audience and sets your materials apart in a crowded marketplace.

Frequently Asked Questions

Your foil printing can last several years without peeling when durability factors like proper substrate and adhesion are met. You’ll get the best longevity by following maintenance tips and handling carefully.

As versatile as the wind, you can confidently apply foil printing techniques to stretchy fabrics. While there are some foil printing limitations, elastic materials like spandex work great for dancewear and activewear.

You’ll be glad to know foil printing is safe for your kids’ clothes when proper safety standards are followed. It works on most fabric types and doesn’t introduce harmful chemicals during application.

You’ll want to wash your foil-printed clothes in cold water (30°C/85°F or below). Following these temperature guidelines and gentle washing techniques will help protect your garment’s special design.

You’ll want to avoid ironing and drying foil-printed items, as heat damages their durability. For best foil printing care, air dry your garments flat and skip the iron altogether.

Conclusion

You’ve now explored the dazzling world of foil printing, where a million metallic possibilities await your creative vision.

From business cards that catch every ray of light to t-shirts that’ll stop traffic with their brilliance, you’ll find this versatile printing method can transform ordinary designs into extraordinary masterpieces.

Whether you’re aiming for subtle elegance or show-stopping glamour, foil printing’s got the power to make your projects absolutely unforgettable.