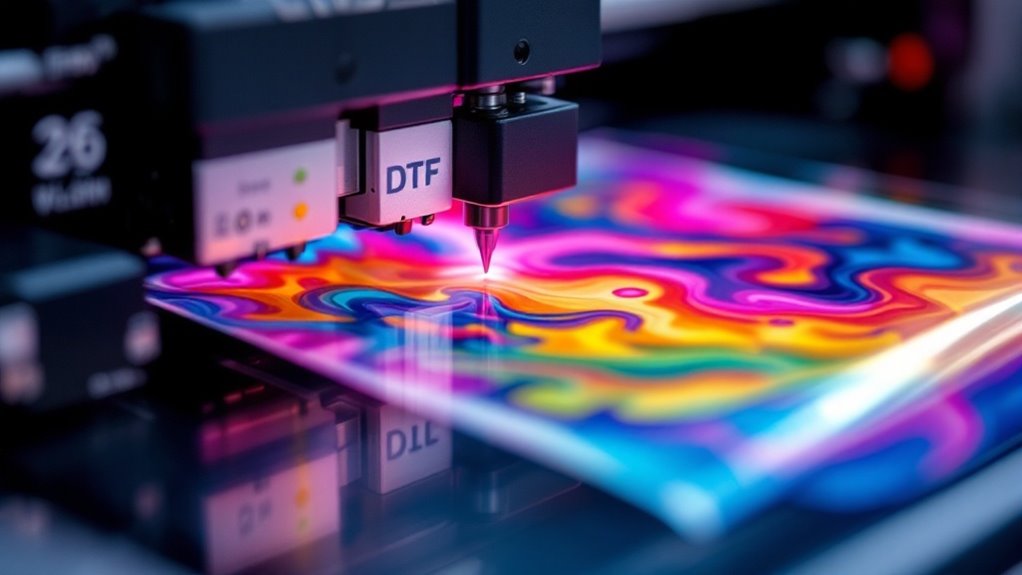

What Is Direct-To-Film DTF Printing?

Direct-to-Film (DTF) printing is a process that involves printing designs on a special film, which is then transferred onto various fabrics using a heat press.

The key steps include printing the design on a PET film, applying an adhesive powder, melting the powder, pre-pressing the fabric, and finally transferring the image using heat and pressure.

DTF printing is compatible with a wide range of materials, such as cotton, polyester, nylon, leather, and denim, allowing for extensive customization and applications in apparel, home décor, and promotional items.

To explore the advantages and techniques of DTF printing, continue on.

Key Takeaways

- DTF printing involves printing designs on PET film for transfer onto various fabrics using a heat press

- The process includes printing, applying adhesive powder, melting the powder, pre-pressing the fabric, and heat transferring the design

- DTF is compatible with a wide range of fabrics, including cotton, polyester, nylon, leather, and denim

- DTF delivers vivid colors, sharp details, and durable prints resistant to fading, cracking, and peeling

- DTF is cost-effective, eco-friendly, and commonly used in apparel, fashion, signage, and promotional products

Definition and Process of DTF Printing

DTF printing, a revolutionary technique, prints designs directly onto a special film, which is then transferred onto various substrates using a heat press.

This versatile method is compatible with a wide range of fabrics, including polyester, cotton, and nylon, allowing for extensive design customization. The DTF printing process begins with printing the design onto a special film using DTF inks.

DTF printing produces high-quality, full-color prints with exceptional detail and color accuracy, ensuring superior print quality. The prints are also durable, resistant to fading, cracking, and peeling, making them suitable for various applications.

DTF Printing Process

To create high-quality prints using DTF technology, you’ll need to follow a step-by-step process that involves printing the design on PET film, applying adhesive powder, melting the powder, pre-pressing the fabric, and transferring the film onto the fabric using a heat press. An automatic take-up reel can be used for easy handling of the printed film.

Effective design techniques and color management are essential for ideal results. The printing process begins with using a specialized DTF printer to print the design on PET film, followed by applying hot melt adhesive powder evenly on the wet ink.

Next, melt the powder using a curing oven or heat press at 160-170°C. Before transferring the film, pre-press the fabric to remove moisture.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

Finally, apply the film to the fabric using a heat press at 160-170°C for 15-20 seconds.

Applications and Versatility of DTF

Beyond its efficient printing process, DTF technology shines in its versatility and wide-ranging applications. It accommodates diverse materials, from various fabric types to non-textile substrates, providing flexibility for printing on a broad range of goods.

DTF printing is extensively used in textile and apparel production, signage, graphics, and creating custom promotional items. It enables unique designs tailored to customer preferences and market trends, enhancing market appeal.

DTF technology is utilized in numerous industries due to its unparalleled versatility and precision in transferring designs onto substrates. It offers high-quality, durable prints with vibrant colors and sharp details, making it ideal for applications in home décor, fashion, and sports apparel.

DTF printing transforms industries and fuels creativity while supporting sustainability practices in digital printing.

Apparel Production

DTF technology revolutionizes apparel production, offering unmatched versatility and efficiency in creating custom garments.

You can quickly respond to changing design trends and market demands by printing high-quality, durable designs on various fabrics, including cotton, polyester, and blends.

DTF printing eliminates the need for expensive transfer papers, reduces overall costs, and offers higher profit margins compared to traditional printing methods. DTF printing also enables short production runs, making it ideal for businesses catering to niche markets or offering personalized products.

With the ability to handle intricate designs and large-volume production, DTF technology streamlines apparel production, making it an attractive option for businesses looking to stay competitive in the fast-paced fashion industry.

Material Versatility

Alongside its impact on apparel production, DTF printing shines in its ability to work with a wide range of materials.

When it comes to material compatibility, cotton is ideal due to its breathability and strong adhesion, while polyester produces vibrant and durable prints suitable for sportswear. Silk’s smooth surface enables crisp, detailed designs with a premium look and feel.

Nylon, although heat-sensitive, can be used with careful adjustments, making it good for athletic wear. Blends and leather are also compatible.

Fabric selection is key, as breathability, durability, weight, thickness, texture, and color all affect print quality and adhesion.

Non-textile materials like paper, wood, metal, and glass can be used with UV DTF printing for special applications, including stickers and decals.

Evaluate the specific benefits of each fabric, such as cotton’s versatility, polyester’s durability, and silk’s luxury finish so you can get the best out of DTF printing.

Comparison With Other Methods

Let’s compare DTF printing with other popular methods, particularly focusing on how it stacks up against DTG regarding the variety of fabrics each can handle.

While DTG works best on cotton and cotton blends, DTF can print on a much wider range of materials, including polyester, nylon, and even leather. DTF’s adaptability to diverse substrates enhances project possibilities.

This versatility makes DTF a more flexible choice for many applications, as you’ll see when we break down the specifics.

1. DTF vs. DTG

Both direct-to-film (DTF) and direct-to-garment (DTG) printing offer unique advantages, but they differ markedly in their printing processes, versatility, and production factors.

DTF prints onto a transfer film, while DTG prints directly onto the garment. DTF is more versatile, suitable for various substrates, while DTG is primarily used for fabrics.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

DTF offers lower production costs, making it cost-effective for small businesses and on-demand printing needs. The key differences between DTF and DTG include:

- Printing process

- Substrate versatility

- Setup costs

- Production flexibility

- Print quality on light and dark fabrics

When choosing between DTF and DTG, evaluate these factors:

| Factor | DTF | DTG |

|---|---|---|

| Substrate variety | Diverse substrates | Primarily fabrics |

| Print quality needs | Finer details | High-quality prints |

| Production volume | Small to large-scale | Smaller batches |

| Cost considerations | Higher initial investment, lower production costs | Lower initial investment, higher production costs |

2. DTF vs. Silkscreen Printing

While Direct-To-Film (DTF) and screen printing both produce high-quality prints on various substrates, they differ considerably in their processes, versatility, and overall efficiency.

DTF printing uses a heat transfer process, allowing for more flexibility in substrate choice and faster production times. In contrast, screen printing requires separate screens for each color, making it more labor-intensive and time-consuming.

DTF printing is suitable for various materials, including cotton, polyester, and blends, making it a versatile option for a wide range of applications.

Key differences between DTF and screen printing:

- Printing process: heat transfer vs. stencils and ink

- Versatility: DTF accommodates more substrates

- Setup: DTF requires less preparation

- Speed: DTF is generally faster and more efficient

- Cost: DTF has lower setup costs, but equipment can be expensive

| Factor | DTF Printing | Screen Printing |

|---|---|---|

| Process | Heat transfer | Stencils and ink |

| Versatility | High | Limited |

| Setup | Minimal | Extensive |

3. DTF vs. Sublimation Printing

Alongside DTG printing, sublimation printing is another popular method for customizing fabrics. However, DTF printing offers several advantages over sublimation:

- Wider fabric compatibility

- Vibrant colors on light and dark fabrics

- Sharper details and color vibrancy

- Ability to print on various materials

- More durable prints

| Feature | DTF Printing | Sublimation Printing |

|---|---|---|

| Fabric Types | Cotton, polyester, blends | Primarily polyester |

| Color Visibility | Light and dark fabrics | White or light-colored fabrics |

| Print Quality | Sharper details, vibrant colors | Vivid but may lack detail |

Despite its popularity, sublimation printing has limitations compared to DTF. It is primarily suitable for polyester fabrics and light-colored materials, while DTF can handle a wider range of substrates.

Additionally, DTF prints offer superior durability and color vibrancy. Sublimation printing requires heat and pressure to transfer the dye onto the fabric, which can be limiting for certain materials and designs.

Advantages

With its impressive quality and performance, DTF printing delivers high-quality prints that showcase vivid colors, sharp details, and photo-realistic depth.

The versatility of DTF printing allows it to accommodate various substrates, including fabrics, plastics, and metals, making it suitable for diverse garment types. This is why it quickly became one of the popular printing method for singapore t shirt printing.

It simplifies the printing process by eliminating the need for pre-treatment of fabrics and enables easy application on difficult or awkward parts of garments. DTF printing withstands 30-50 washes, maintaining its quality over time.

| Advantages | Benefits |

|---|---|

| High-quality prints | Vivid colors and sharp details |

| Versatility | Accommodates various substrates and garment types |

| Efficiency | Faster turnaround times and simplified process |

| Cost-effectiveness | Reduces setup costs and white ink usage |

| Sustainability | Eliminates screen setup costs and increases profits |

DTF printing aligns with current design trends and contributes to market growth.

Equipment and Supplies

To achieve the remarkable results and efficiency that DTF printing offers, you’ll need the right equipment and supplies. DTF printers, like those from Procolored, Roland, and QUATRO, feature Epson i3200 print heads and white ink auto circulation supply systems for ideal performance. Heat press machines are essential for transferring designs onto garments.

You’ll also need high-quality DTF films, eco-friendly water-based inks, and thermo-adhesive powders. Proper equipment maintenance is vital for consistent print quality and longevity. Regular cleaning, calibration, and replacement of consumables will keep your DTF printer running smoothly.

When sourcing supplies, look for reputable vendors that offer extensive ranges of compatible films, inks, and powders. Choosing the right supplies will guarantee vibrant, durable prints and seamless compatibility with your DTF printing system.

Industry Usage

Let’s explore the popular business applications of DTF printing and how it benefits print-on-demand services.

DTF printing is widely used in various industries, including apparel, fashion, signage, and promotional products. Sports teams utilize DTF transfers for customizing uniforms, jerseys, and apparel.

Its versatility and high-quality output make it an attractive option for businesses looking to offer personalized and custom-printed items.

Popular Business Applications

DTF printing has become a popular choice for businesses across various industry sectors, thanks to its versatility and cost-effectiveness. As market growth continues, many companies are adopting this technology to keep up with current business trends.

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

DTF printing is widely used in fashion, sportswear, and promotional items, catering to both small businesses and large-scale production operations. It supports a variety of materials, including cotton, polyester, nylon, and leather, making it ideal for creating detailed designs on both light and dark garments. DTF printing reduces material waste, making it an eco-friendly option for businesses.

Additionally, DTF printing offers versatility in textile applications, such as apparel and interior décor. With its ability to produce high-quality prints on various substrates, DTF printing has become an attractive option for businesses looking to stay competitive in their respective markets.

Print-on-Demand Benefits

When contemplating the benefits of print-on-demand for businesses, it’s essential to understand how this technology can help optimize operations and improve overall efficiency.

By reducing overhead costs, increasing flexibility and customization, minimizing inventory risk, and enabling short lead times, print-on-demand offers significant advantages.

It allows you to respond quickly to print on demand trends and seize market opportunities without the financial burden of maintaining large inventories.

With the ability to test new products and designs, you can adapt to changing customer preferences and market conditions. The global POD market is projected to reach $45.6 billion by 2031, driven by growing popularity among entrepreneurs and content creators.

Print-on-demand also streamlines your operations by eliminating the need for extensive inventory management, freeing up resources for other aspects of your business.

High Demand Products

If you’re thinking about starting a direct-to-film (DTF) printing business, it’s essential to know which products are in high demand.

By staying up-to-date with market trends and customer preferences, you can guarantee your business offers the most sought-after items.

Some of the top-selling DTF-printed products include:

- Apparel and fashion items like t-shirts, hoodies, and accessories

- Home decor products such as pillow covers, wall hangings, and curtains

- Promotional and event merchandise, including banners and corporate gifts in Singapore

- Tech and gadget accessories like phone cases, laptop sleeves, and gaming gear

- Personalized products that cater to the increasing demand for unique and customized designs tailored to individual consumer needs.

Frequently Asked Questions

Depending on the DTF printer type and brand you choose, costs range from $1,500 for entry-level models to over $15,000 for high-end commercial printers with advanced features and superior print quality.

You’ll face a moderate learning curve with DTF printing. To shorten it, seek out extensive learning resources that cover the entire process. Troubleshooting tips from experienced printers can also help you overcome common hurdles.

Lightning-fast designs are at your fingertips with DTF printing! Design speed varies based on complexity, but printing efficiency is high once the process begins. Expect anywhere from minutes to a couple of hours for completion.

Yes, DTF printing is ideal for your small business’s production needs. Its cost-effectiveness, versatility, and efficiency make it a practical solution for small-scale production, allowing you to create high-quality prints with minimal waste.

With proper care, your DTF prints can last 50+ washes. Like a well-tended garden, their longevity blooms when you use high-quality materials, follow washing instructions, and shield them from harsh environmental factors.

Conclusion

To summarize, you’ve learned that DTF printing is a versatile and efficient method for creating high-quality, customized apparel and products.

With its ability to print on various fabrics and materials, it’s no wonder that the global DTF printing market is expected to reach $3.2 billion by 2026.

Whether you’re a small business owner or a large-scale manufacturer, investing in DTF printing equipment and supplies can help you meet the growing demand for personalized products.

If you are looking to customise your order with Direct-To-Film printing, check out our projects with DTF prints here, DTF recent projects.