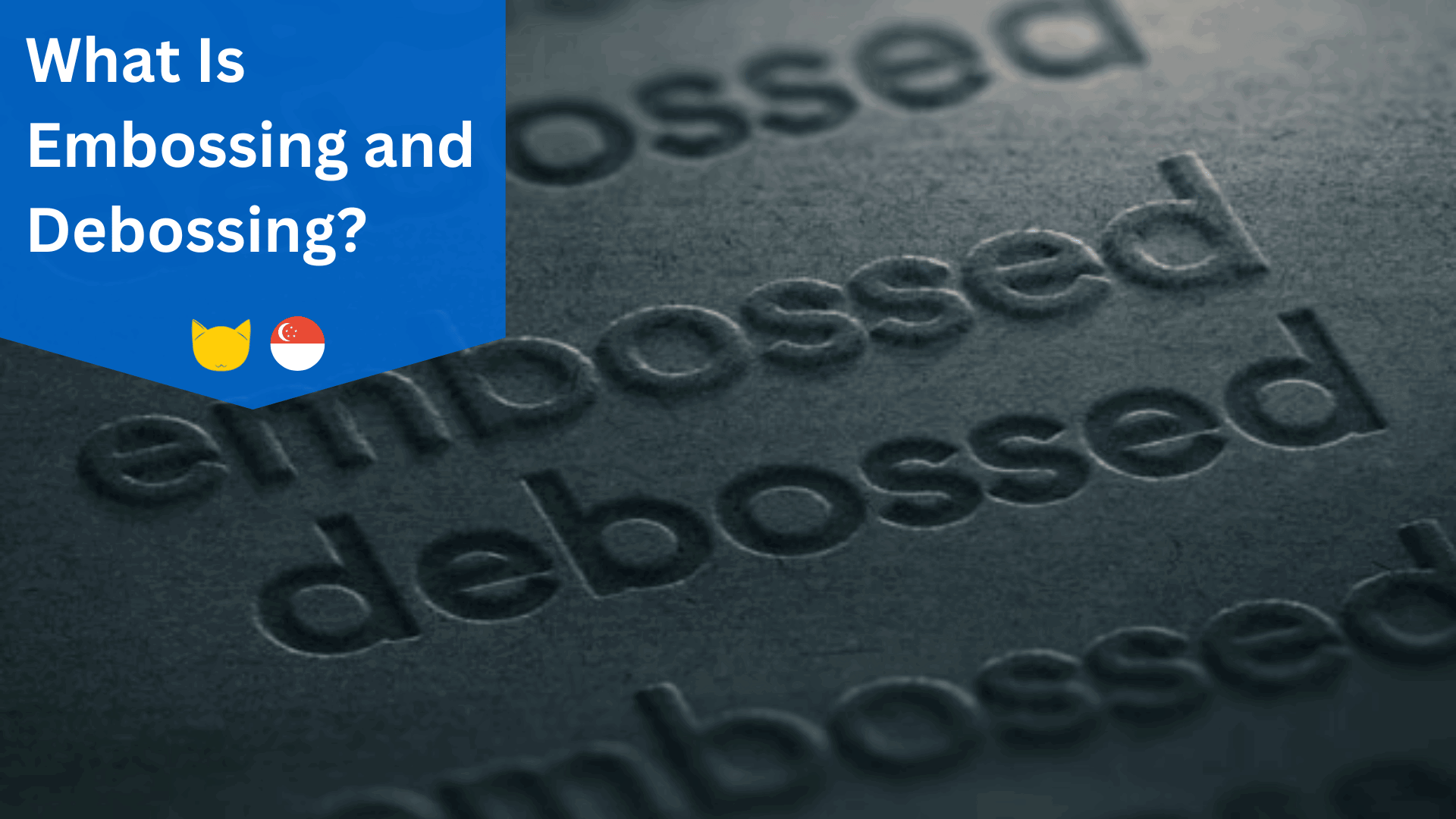

What Is Embossing and Debossing?

Embossing and debossing are two techniques used to create raised or depressed designs on various materials, such as paper, cardstock, leather, and metal.

Embossing involves using a die to press a design into the material from behind, creating a raised effect; debossing uses a die to press a design into the material from the front, creating an indented effect.

Both techniques add depth, texture, and visual interest to packaging, stationery, and promotional items. Embossing is suitable for creating eye-catching designs, while debossing is ideal for subtle, elegant effects.

Comparing the advantages and limitations of each technique will help you determine which is best for your project.

Key Takeaways

- Embossing creates a raised design on a surface, while debossing creates an indented design.

- Embossing uses two dies to raise the design, while debossing uses one die to press the design into the material.

- Both techniques add visual interest, texture, and depth to various materials like paper, leather, and metal.

- Embossing and debossing are commonly used in luxury branding, packaging, and promotional items to enhance aesthetics and user experience.

- Material selection, quality control, and proof samples are crucial considerations for achieving the desired outcome in both processes.

How does Embossing work?

Let’s explore the enchanting process of embossing and how it creates stunning raised designs on various materials. The process involves:

- Creating a metal die plate with the raised design

- Pressing the die into the material from behind

- Reusing the durable die for multiple projects

Embossing techniques like using foils and multi-level dies add depth and complexity. The illusory depth makes embossings appear deeper than they are. Blind embossing is a clean look achieved without using any inks or foils.

| Material | Technique | Effect |

|---|---|---|

| Paper | Foil | Luxe |

| Metal | Multi-die | Depth |

| Cloth | Debossing | Tactile |

When considering embossing designs, choose ideal sections like logos and use vector art files for best results. Keep in mind that material thickness determines the total embossing height.

Pros and Cons of Embossing

While embossing offers a range of advantages, such as creating a tactile experience, enhancing sophistication, and providing durability, it also comes with some drawbacks.

Embossing is widely used in luxury branding and packaging for added prestige. You should consider the high cost associated with creating dies, the color limitations, and the labor-intensive nature of the process.

Embossing can also be used on cloth materials, mainly for t shirt printing in singapore, to create unique designs on custom apparels!

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

Let’s explore these pros and cons in more detail to help you make an informed decision about whether embossing is the right choice for your project.

Pros

Embossing offers a range of compelling benefits that enhance the visual and tactile appeal of printed materials. Here are three key advantages:

- Versatility: Embossing techniques can be applied to a variety of materials, from paper and cardstock to leather and metal, allowing for creative flexibility.

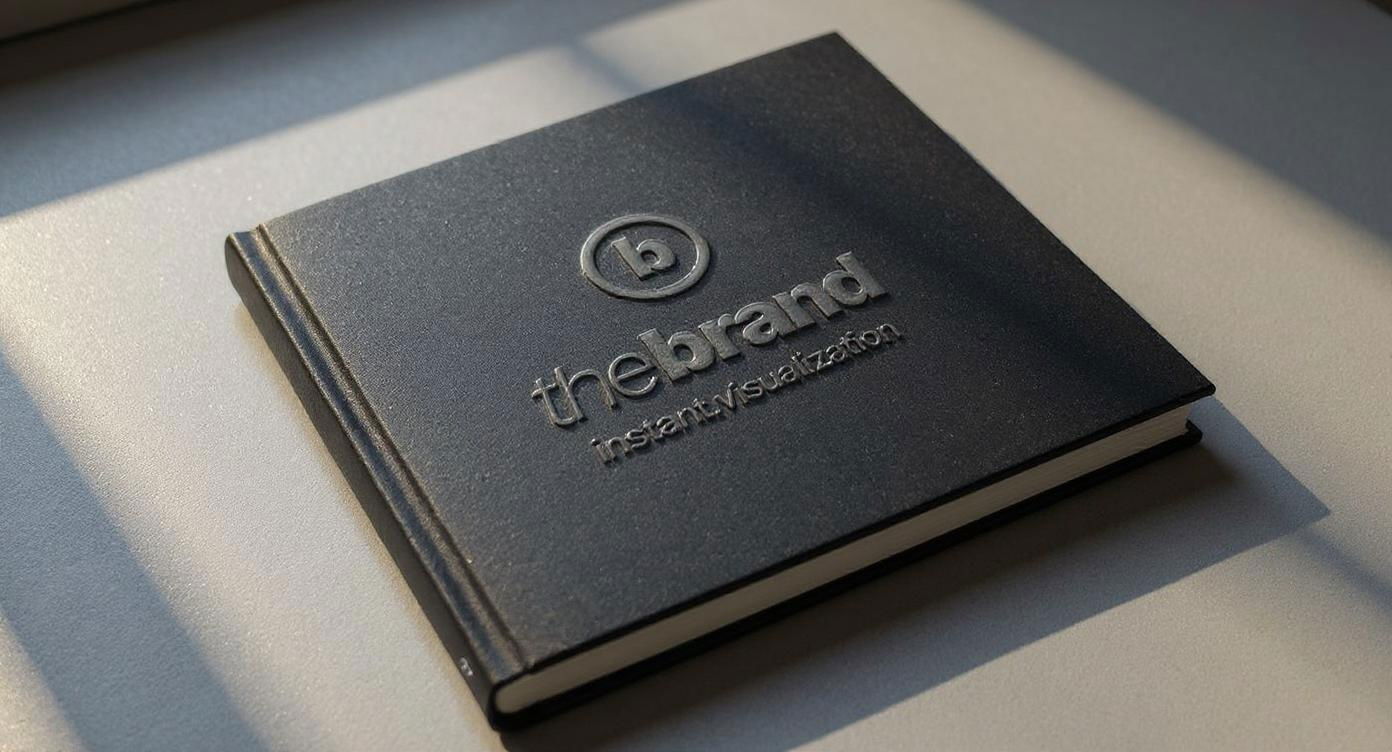

- Durability: Embossed designs are more resistant to wear and tear compared to flat printing, making them ideal for products that require longevity, such as business cards or book covers.

- Premium appearance: Embossing adds depth, dimension, and a luxurious feel to printed pieces, elevating the perceived value and sophistication of the design. Embossing can also enhance the overall user experience by providing tactile feedback that reinforces the message and creates an interactive experience with printed materials.

Whether you’re creating packaging, invitations, or branding materials, embossing can help your products stand out and leave a lasting impression on your audience.

Cons

Despite its advantages, embossing comes with some drawbacks that you should consider before choosing this technique for your project. Embossing techniques can be limited by:

- Material suitability, as embossing works best on malleable materials like paper and leather, but not on delicate or highly flexible ones

- Higher costs compared to standard printing methods due to the need for specialized equipment and precise processing

- Design challenges, such as difficulty achieving fine details on certain materials and managing complex designs or large print runs

Additionally, embossed areas may show wear and flattening over time, especially on frequently handled items, reducing the design’s durability.

Frequent handling can impact the longevity of embossed items. When deciding if embossing is right for your project, carefully consider these limitations alongside the unique, tactile benefits it provides.

How does Debossing work?

Creating a debossed design is a multi-step process that requires specialized equipment and expertise. Here’s how it works:

- Design digitization and die creation

- Positioning the die and material in the press

- Applying heat and pressure to create the debossed design

The process involves engraving a metal die with the design, heating it to a specific temperature based on the material, and pressing it into the surface using a hydraulic press.

The depth of the design is determined by the pressure applied and the depth of the engraving on the die.

| Debossing Techniques | Debossing Materials | Equipment Needed |

|---|---|---|

| Blind debossing | Paper | CAD software |

| Registered debossing | Leather | Engraving machine |

| Combination debossing | Plastic | Debossing press |

Pros and Cons of Debossing

Now that you understand how debossing works, let’s examine its advantages and disadvantages.

Debossing offers several benefits, such as durability, cost-effectiveness, and aesthetic appeal, but it also has some limitations.

Debossing is often preferred for luxury packaging and labels, as it adds a subtle sophistication and elegance to the design.

We’ll explore these pros and cons in detail to help you make an informed decision when considering debossing for your project.

Pros

Debossing offers a unique set of advantages that make it a popular choice for various design projects. Here are three key benefits:

- Dimensional depth: Debossing creates a layered effect that adds visual interest and texture to designs, making them stand out.

- Versatility: This technique can be applied to a wide range of materials, from paper and leather to metal, allowing for diverse design applications.

- Durability: Debossed designs are permanent and resistant to wear and tear, ensuring your artwork remains intact over time. Debossing is often more cost-effective than embossing, especially for simpler designs and larger production runs.

Debossing techniques involve pressing a die into the material from the front, creating a recessed impression.

This process is well-suited for thicker materials like cardstock or leather, resulting in elegant and understated designs that are perfect for branding and logos.

Cons

While debossing offers several advantages, it’s important to take into account its limitations before incorporating it into your design project. When considering debossing techniques, keep in mind that:

- Material compatibility is vital, as not all materials are suitable for debossing due to thickness, softness, or heat sensitivity.

- Complex designs with intricate details or curves may lose clarity during the debossing process, so simpler designs work best.

- The custom-made die required for debossing can increase costs and lead to longer production times compared to other printing methods. Bulk orders may reduce per-unit costs for debossing projects.

Additionally, quality control is essential to guarantee consistent and precise results. Improper tooling, inexperienced operators, or material defects can result in uneven or substandard debossing.

Embossing vs Debossing

Although embossing and debossing are both techniques that create tactile designs on various materials, they differ in their methods and visual effects.

Embossing techniques raise the design above the material surface, using heat and pressure to create a 3D effect. This process typically involves:

Are You Looking For Customization?

If you're looking for T-Shirts or Corporate Gifts of at least 20 pieces and above, we can help you!

- Two dies (male and female)

- Higher temperatures

- Suitable for paper, cardstock, and metals

In contrast, debossing applications create an indented design, often using a single die and less heat. Debossing works well on softer materials like leather and textiles, as it doesn’t interfere with the opposite side of the material.

Cosmetic packaging often employs embossing and debossing techniques to create a luxurious feel for their products.

| Characteristic | Embossing | Debossing |

|---|---|---|

| Effect | Raised | Indented |

| Dies | 2 (male & female) | 1 |

| Heat | Higher | Lower |

| Materials | Paper, cardstock, metals | Leather, textiles, vinyl |

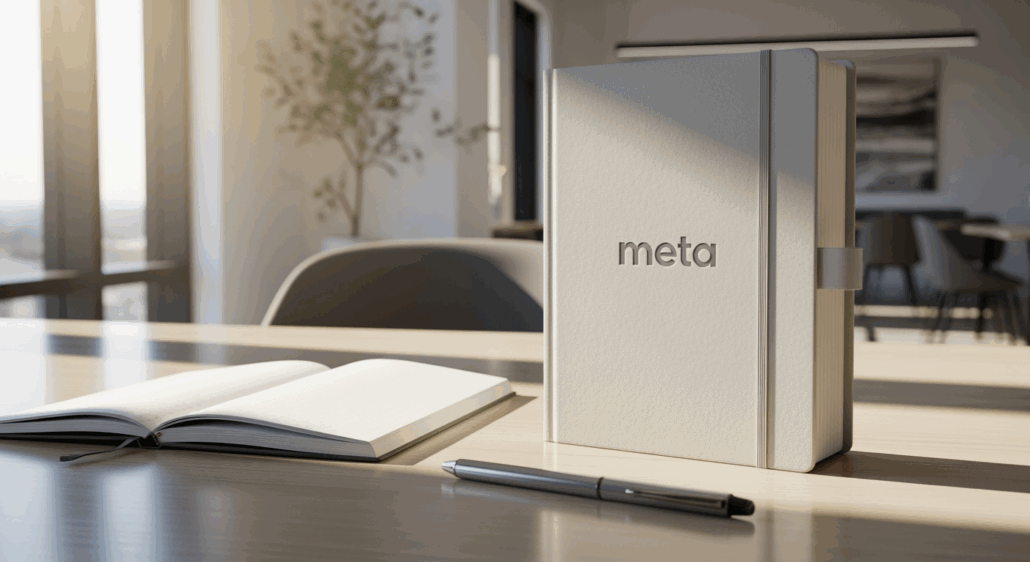

Uses of Debossing in Custom Corporate Gifts

When you’re looking to create promotional corporate gifts singapore, that leave a lasting impression, debossing offers a versatile and cost-effective solution.

This technique works well on a variety of materials, including leather goods, hardwoods, thick plastics, and stainless steel, making it suitable for a wide range of products.

Debossing adds a tactile appeal to your custom branding, creating a refined and understated look that’s perfect for corporate gifts and promotional items.

It’s also a durable option, as debossed designs are less prone to wear and damage compared to embossing. Debossing allows for both sides of the material to be utilized without interference, making it an excellent choice for dual-sided designs.

Whether you’re creating leather accessories, commemorative plaques, or technology products, debossing can help you achieve a sophisticated, long-lasting design that effectively represents your brand and leaves a memorable impression on your recipients.

Important Takeaways

Embossing and debossing are two powerful techniques that can elevate your designs and leave a lasting impression on your audience.

When considering these techniques for your design applications, keep in mind their distinct visual effects and suitability for different materials.

Embossing creates a raised, eye-catching effect, while debossing provides a subtle, elegant impression. Be mindful of material selection, as some materials may not be ideal for these processes due to heat sensitivity or thinness.

Combining embossing and debossing can add depth and interest to your designs, while foil stamping can enhance the visual intensity of embossed elements.

By understanding the key differences and considerations between embossing and debossing, you can make informed decisions and create stunning, impactful designs that stand out from the crowd.

Frequently Asked Questions

Blind embossing techniques create raised designs without ink or foil, while foil embossing applications combine embossing with foil stamping for a shiny, colored effect. The former is subtle; the latter, luxurious and eye-catching.

The production timeline varies based on the complexity of the design and embossing techniques used. Expect anywhere from a few days to several weeks.

Embossing works best on thicker paper types and sturdy materials. Thin or low-quality papers may tear or crumple under the process. It’s not suitable for all materials, so consider the material limitations before embossing.

Yes, there’s usually a minimum order quantity for embossing services. It varies by provider and project specifics, but larger quantities are more cost-effective due to setup fees and die costs being spread out.

You’re right to wonder about embossing costs. Several factors influence pricing, but compared to regular printing, embossing is typically more expensive due to the specialized equipment, craftsmanship, and materials needed to achieve its raised, tactile effect.

Conclusion

You now have a solid understanding of embossing and debossing, two techniques that add depth and dimension to various materials.

While they may seem like two peas in a pod, each has its own unique characteristics, advantages, and disadvantages.

Whether you’re creating customised corporate gifts or exploring new design possibilities, knowing the difference between embossing and debossing will help you make informed decisions and achieve the desired look and feel for your project.